ISO 9001

ISO 9001 is an internationally recognized standard for quality management and applies to all types of organizations, regardless of their nature, size, or the products or services they provide.

ISO 9001 outlines a management model which, when implemented, ensures the expected quality of an organization’s products and services, with the ultimate goal of customer satisfaction.

With over 1.1 million certifications worldwide, ISO 9001 certification helps organizations demonstrate to their clients that they consistently and reliably deliver products and services that meet agreed-upon quality standards.

Benefits

The main benefits of implementing and certifying a Quality Management System according to ISO 9001 include:

- Enhanced business reputation: ISO 9001 helps secure customer trust by reinforcing the company’s reputation for delivering quality products and services.

- Access to international markets: This certification creates opportunities for exports and international partnerships by increasing the reliability and credibility of the business.

- Reduction of production costs: Through the optimization of resource and time management, ISO 9001 leads to economies of scale and cost reduction.

- Employee awareness and engagement: It fosters employee involvement and supports continuous improvement in quality management.

- Increased customer satisfaction: The consistent delivery of products and services that meet customer expectations leads to greater satisfaction and loyalty.

- Continuous process improvement: Through the use of objective monitoring and measurement tools, organizations can enhance their processes and create added value for the business.

The new version

The New Edition ISO 9001:2015 “Quality Management Systems – Requirements”

The ISO 9001 standard was first introduced in 1987 by the International Organization for Standardization (ISO), following the British standard BS 5750. The language of this initial version was heavily influenced by the strict standards of the U.S. military, making it more accessible to industrial manufacturing rather than to other sectors of economic activity.

Although ISO’s original intention was to establish fundamental Quality Management Principles within the business community through the application of such a standard, this vision was not fully realized. The 1994 revision (ISO 9000:1994) made the first attempt to introduce the concept of “prevention.” Unfortunately, companies had already become accustomed to implementing the standard in a way that produced “shelves” of procedures, often leading to bureaucracy. As a result, the idea of continual improvement through prevention proved particularly difficult to apply in such an environment.

The 2000 revision of the standard attempted a radical shift in mindset. It placed the concept of quality management at the core of the standard. Thus, the eight fundamental principles of quality management were introduced, with the aim of establishing a common foundation for all quality management-related standards.

Today, nearly 40 years since the original release of ISO 9001, the ISO Technical Committee responsible for the standard has concluded that a review and revision is imperative in order to:

- Establish a common format and language across all management system standards, enabling alignment and integration (e.g., with ISO 14001, OHSAS 18001, etc.). To this end, ISO designed a High-Level Structure for all Management System Standards, incorporating a unified structure, terms, and concepts.

- Reduce documentation requirements, placing greater emphasis on organizational value and the customer.

- Maintain the relevance of Quality Management Systems (QMS) in today’s marketplace.

With this new edition (ISO 9001:2015), ISO aims for a philosophical shift while preserving its orientation around the eight quality management principles and its fundamental Plan – Do – Check – Act approach to quality management.

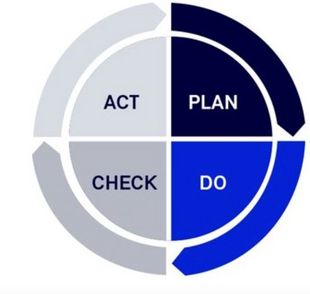

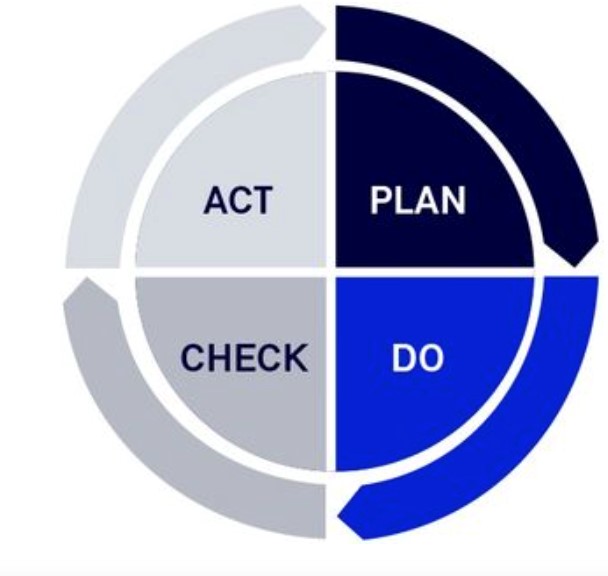

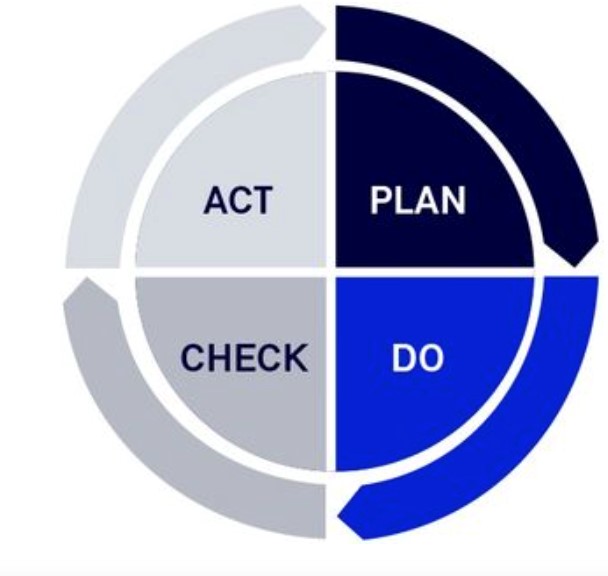

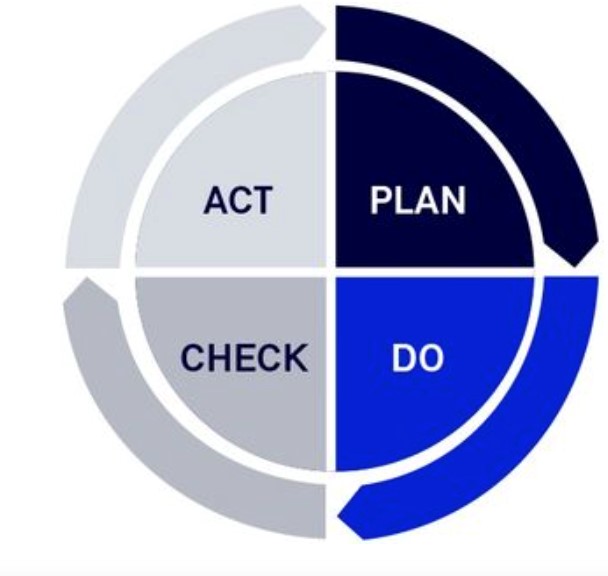

The Approach: Plan-Do-Check-Act

ISO 9001 certification defines the requirements for quality management across the entire value chain.

It is based on the Plan-Do-Check-Act (PDCA) model, which is divided into four phases. The goal is the continuous improvement of individual processes as well as the overall system. As the name implies, this means: plan the processes – implement them – monitor and check them – and act accordingly.

The constantly recurring PDCA cycle is a management tool that leads to a process of continual improvement—both for the individual processes within the company and the overall system, including its products and services.

This approach prevents stagnation and ensures that companies continuously adapt to changing conditions. Choosing such a management system means entering a path of ongoing development.

The Key Changes in the New Version of the Standard

September 2015: 30 September 2015 – Publication of ISO 9001:2015

18 Months: Within 18 months from the publication date, all new certifications must be based on the 2015 version of the Standard.

3 Years: All certified organizations must have transitioned to the 2015 version of the Standard within three years.]

The language and intent of the ISO 9001 standard have significantly evolved compared to its previous versions. New definitions have been introduced regarding interested parties, the context of the organization, and risks.

The requirements most likely to have the greatest impact on organizations include:

- Determining relevant internal and external issues that could influence the achievement of the desired outcomes of the QMS

- Identifying relevant interested parties and their requirements

- Integrating QMS objectives into operational processes

- Aligning the quality policy and objectives with the organization’s strategic direction

- Considering QMS performance as part of strategic planning

- Identifying and monitoring the organization’s threats and opportunities

- Conducting management reviews that incorporate all of the above elements.

With its team of experienced auditors, TÜV HELLAS has certified more than 10,000 companies in Greece, Cyprus, Lebanon, Romania, Bulgaria, Egypt, Turkey, and the Middle East, holding a leading position in Greece. Additionally, TÜV HELLAS is already conducting audits in accordance with the new ISO 9001:2015 version.

Please Contact Us

282, Mesogeion Av.

155 62 Cholargos, Greece

Tel.: +30 215 215 7452

Fax: +30 210 6528025

certification@tuvhellas.com